What are the Product Standards for Porcelain Tube Resistors?

I. Introduction

Porcelain tube resistors are essential components in various electrical circuits, known for their durability and reliability. These resistors are made from high-quality porcelain, which provides excellent thermal and electrical insulation. As with any electrical component, product standards play a crucial role in ensuring their safety, performance, and compatibility. This article aims to explore the product standards for porcelain tube resistors, highlighting their importance, key standards, testing methods, and future trends.

II. Understanding Porcelain Tube Resistors

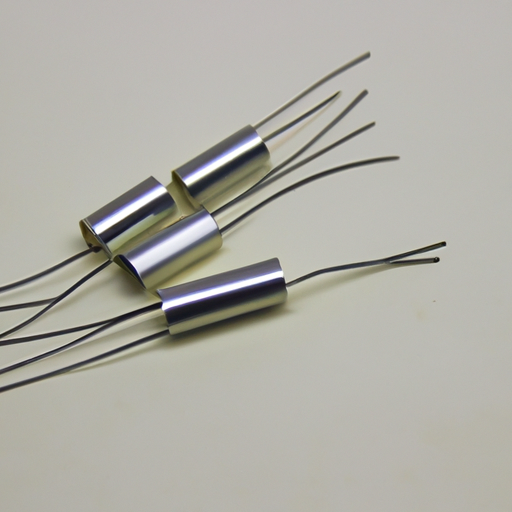

A. Composition and Construction

Porcelain tube resistors are primarily composed of a ceramic material known as porcelain, which is a mixture of clay, feldspar, and quartz. The manufacturing process involves shaping the mixture into tubes and firing them at high temperatures to achieve the desired hardness and electrical properties. The resistive element is typically made from a carbon-based material or metal oxide, which is applied to the surface of the porcelain tube.

B. Functionality and Applications

Porcelain tube resistors serve a critical role in electrical circuits by limiting current flow and dissipating energy as heat. They are commonly used in power supplies, motor control circuits, and various industrial applications. Their ability to withstand high temperatures and harsh environments makes them suitable for use in automotive, aerospace, and telecommunications industries.

III. Importance of Product Standards

A. Ensuring Safety and Reliability

Product standards are vital for ensuring the safety and reliability of porcelain tube resistors. They provide guidelines for manufacturing processes, materials, and testing methods, helping to minimize the risk of failure and accidents in electrical systems.

B. Facilitating Compatibility and Interoperability

Standards facilitate compatibility and interoperability between different manufacturers' products. This is particularly important in industries where multiple components must work together seamlessly. Adhering to established standards ensures that porcelain tube resistors can be easily integrated into various systems.

C. Enhancing Performance and Longevity

By following product standards, manufacturers can enhance the performance and longevity of porcelain tube resistors. Standards often include specifications for temperature ratings, resistance values, and tolerance levels, ensuring that the resistors can operate effectively under specified conditions.

D. Regulatory Compliance and Market Access

Compliance with product standards is often a requirement for regulatory approval and market access. Manufacturers must demonstrate that their products meet relevant standards to sell them in specific regions or industries. This compliance not only helps in gaining market entry but also builds trust with customers.

IV. Key Product Standards for Porcelain Tube Resistors

A. International Electrotechnical Commission (IEC) Standards

The IEC develops international standards for electrical and electronic devices. Several IEC standards are relevant to porcelain tube resistors, including:

1. **IEC 60115**: This standard outlines the general requirements for fixed resistors, including porcelain tube types. It covers aspects such as temperature coefficients, resistance values, and testing methods.

2. **IEC 60216**: This standard specifies the thermal endurance properties of electrical insulating materials, which is crucial for ensuring the reliability of porcelain tube resistors under high-temperature conditions.

B. American National Standards Institute (ANSI) Standards

ANSI oversees the development of standards in the United States. Key ANSI standards for resistors include:

1. **ANSI C39.1**: This standard provides guidelines for the performance of resistors, including porcelain tube types, ensuring they meet specific electrical and mechanical requirements.

2. **ANSI/IEEE C57.12.00**: This standard addresses the general requirements for transformers and associated equipment, which may include porcelain tube resistors in their design.

C. Underwriters Laboratories (UL) Standards

UL is a global safety certification organization that develops standards for electrical components. The importance of UL certification for porcelain tube resistors cannot be overstated, as it signifies that the product has been tested for safety and performance. Relevant UL standards include:

1. **UL 1412**: This standard covers the safety requirements for resistors, including porcelain tube types, ensuring they can withstand environmental stresses without failure.

2. **UL 94**: This standard evaluates the flammability of plastic materials used in electrical devices, which may apply to the insulation materials surrounding porcelain tube resistors.

D. Other Relevant Standards and Certifications

In addition to IEC, ANSI, and UL standards, several other certifications are important for porcelain tube resistors:

1. **ISO Standards**: The International Organization for Standardization (ISO) develops standards that ensure quality management and environmental responsibility in manufacturing processes.

2. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electrical and electronic equipment, ensuring that porcelain tube resistors are safe for the environment.

3. **REACH Regulations**: The Registration, Evaluation, Authorisation, and Restriction of Chemicals (REACH) regulation ensures that chemical substances used in products are safe for human health and the environment.

V. Testing and Quality Assurance

A. Testing Methods for Porcelain Tube Resistors

To ensure compliance with product standards, various testing methods are employed:

1. **Electrical Testing**: This includes measuring resistance values, temperature coefficients, and power ratings to ensure that the resistors meet specified performance criteria.

2. **Mechanical Testing**: Mechanical tests assess the physical durability of porcelain tube resistors, including their ability to withstand mechanical stress and vibration.

3. **Environmental Testing**: Environmental tests evaluate the performance of resistors under extreme conditions, such as high temperatures, humidity, and corrosive environments.

B. Quality Assurance Processes

Quality assurance is critical in the manufacturing of porcelain tube resistors. Key processes include:

1. **Manufacturing Quality Control**: Implementing strict quality control measures during the manufacturing process helps identify defects early and ensures that products meet established standards.

2. **Certification Processes**: Obtaining certifications from recognized standards organizations demonstrates compliance with safety and performance standards, enhancing marketability.

3. **Continuous Improvement Practices**: Manufacturers should adopt continuous improvement practices to refine their processes and products, ensuring they remain competitive and compliant with evolving standards.

VI. Challenges in Meeting Product Standards

A. Variability in Manufacturing Processes

Variability in manufacturing processes can lead to inconsistencies in product quality. Manufacturers must implement robust quality control measures to minimize this variability and ensure compliance with standards.

B. Evolving Technology and Standards

As technology advances, product standards also evolve. Manufacturers must stay informed about changes in standards and adapt their processes accordingly to maintain compliance.

C. Global Market Considerations

Navigating the complexities of global markets can be challenging, as different regions may have varying standards and regulations. Manufacturers must ensure that their products meet the specific requirements of each market they serve.

D. Cost Implications for Manufacturers

Meeting product standards can involve significant costs, including testing, certification, and quality control measures. Manufacturers must balance these costs with the need to produce high-quality, compliant products.

VII. Future Trends in Porcelain Tube Resistor Standards

A. Innovations in Materials and Technology

The future of porcelain tube resistors may see innovations in materials and manufacturing processes, leading to improved performance and sustainability. Research into alternative materials could enhance the thermal and electrical properties of resistors.

B. Increasing Emphasis on Sustainability

As industries move towards more sustainable practices, there will be a growing emphasis on environmentally friendly materials and processes in the production of porcelain tube resistors. Compliance with sustainability standards will become increasingly important.

C. Anticipated Changes in Regulatory Frameworks

Regulatory frameworks are likely to evolve, with stricter requirements for safety, environmental impact, and product performance. Manufacturers must stay ahead of these changes to ensure compliance.

D. The Role of Industry Collaboration in Standard Development

Collaboration among industry stakeholders, including manufacturers, standards organizations, and regulatory bodies, will be essential in developing and updating product standards. This collaboration can help ensure that standards remain relevant and effective in addressing emerging challenges.

VIII. Conclusion

In conclusion, product standards for porcelain tube resistors are crucial for ensuring safety, performance, and marketability. These standards provide guidelines for manufacturing, testing, and quality assurance, helping manufacturers produce reliable and compliant products. As technology and regulatory frameworks continue to evolve, it is essential for manufacturers and stakeholders to prioritize compliance with these standards to meet the demands of the market and ensure the safety of electrical systems.

IX. References

1. International Electrotechnical Commission (IEC) - [IEC Standards](https://www.iec.ch)

2. American National Standards Institute (ANSI) - [ANSI Standards](https://www.ansi.org)

3. Underwriters Laboratories (UL) - [UL Standards](https://www.ul.com)

4. International Organization for Standardization (ISO) - [ISO Standards](https://www.iso.org)

5. European Commission - [RoHS Directive](https://ec.europa.eu/environment/waste/rohs_eee/index_en.htm)

6. European Chemicals Agency - [REACH Regulation](https://echa.europa.eu/regulations/reach)

This comprehensive overview of product standards for porcelain tube resistors highlights their significance in ensuring safety, reliability, and performance in electrical applications. Manufacturers and stakeholders must remain vigilant in adhering to these standards to foster innovation and maintain market competitiveness.