What Industries Are the Application Scenarios of Grounding Resistors Included In?

I. Introduction

Grounding resistors play a crucial role in electrical systems, serving as a vital component for ensuring safety and reliability. These devices are designed to limit fault currents and stabilize voltage levels, thereby protecting equipment and personnel from electrical hazards. In this blog post, we will explore the various industries that utilize grounding resistors, the specific application scenarios in which they are employed, and the importance of grounding in maintaining electrical safety.

II. Understanding Grounding Resistors

A. Function and Purpose

Grounding resistors serve two primary functions: voltage limitation and fault current management. When a fault occurs in an electrical system, such as a short circuit, the grounding resistor helps to limit the amount of current that can flow through the ground. This limitation is essential for protecting sensitive equipment and ensuring the safety of personnel working in proximity to electrical systems.

B. Types of Grounding Resistors

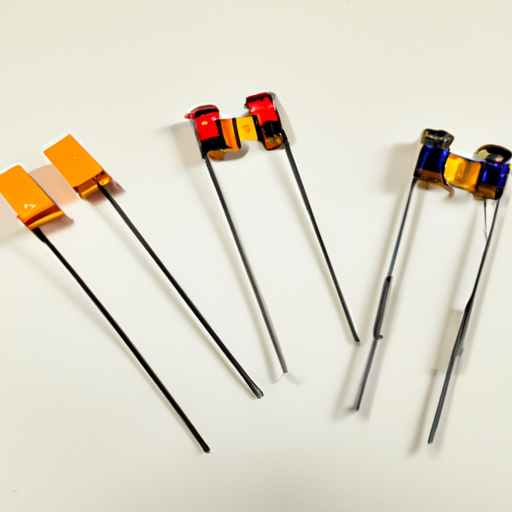

There are several types of grounding resistors, each designed for specific applications:

1. **Neutral Grounding Resistors (NGR)**: These are used to connect the neutral point of a transformer or generator to the ground. They help to limit the fault current during a ground fault condition.

2. **System Grounding Resistors**: These resistors are used in various electrical systems to provide a path for fault currents while maintaining system stability.

3. **Other Variants**: Additional types of grounding resistors may include variable resistors and specialized designs for unique applications.

III. Key Industries Utilizing Grounding Resistors

A. Power Generation and Distribution

The power generation and distribution industry is one of the primary sectors that rely on grounding resistors. In electrical substations, grounding resistors play a critical role in protecting generators and transformers from damage due to fault currents. By limiting the fault current, these resistors help to ensure the stability and reliability of the power supply.

B. Telecommunications

In the telecommunications industry, grounding resistors are essential for ensuring signal integrity and protecting equipment from lightning strikes. Proper grounding helps to prevent damage to sensitive communication equipment, ensuring uninterrupted service and reliable data transmission.

C. Manufacturing and Industrial Facilities

Manufacturing and industrial facilities utilize grounding resistors to protect equipment and ensure safety compliance. In environments where heavy machinery operates, grounding resistors help to mitigate the risk of electrical faults, thereby safeguarding both personnel and equipment.

D. Renewable Energy Sector

The renewable energy sector, particularly in wind and solar energy systems, faces unique challenges related to grid integration. Grounding resistors are employed to manage fault currents and stabilize voltage levels, ensuring that renewable energy sources can be safely and effectively integrated into the existing power grid.

E. Transportation

In the transportation industry, grounding resistors are used in rail systems and electric vehicles (EVs) to ensure safety and reliability. For rail systems, proper grounding is essential for the safe operation of electric trains, while EV charging stations require effective grounding to protect users and equipment.

F. Data Centers and IT Infrastructure

Data centers and IT infrastructure rely heavily on grounding resistors to maintain the integrity of IT equipment. Grounding is crucial for reducing electromagnetic interference (EMI), which can disrupt the operation of sensitive electronic devices. By implementing effective grounding practices, data centers can enhance the reliability and performance of their systems.

IV. Application Scenarios of Grounding Resistors

A. Fault Detection and Isolation

Grounding resistors play a vital role in fault detection and isolation. By limiting fault currents, these resistors enable early warning systems to detect electrical faults before they escalate into more significant issues. This capability minimizes downtime and enhances the overall reliability of electrical systems.

B. Lightning Protection Systems

In lightning protection systems, grounding resistors are essential for ensuring safety and equipment longevity. By providing a low-resistance path for lightning strikes, these resistors help to protect structures and equipment from the damaging effects of electrical surges.

C. Electrical Safety in Hazardous Locations

In industries such as oil and gas and chemical processing, grounding resistors are critical for maintaining electrical safety in hazardous locations. These environments often contain flammable materials, making effective grounding essential for preventing electrical fires and explosions.

D. Grounding in High Voltage Applications

Grounding resistors are also employed in high voltage applications, such as transmission lines and substations. Proper grounding practices in these settings are crucial for ensuring the safety and reliability of the electrical grid.

V. Regulatory Standards and Best Practices

A. Overview of Relevant Standards

Several regulatory standards govern the use of grounding resistors, including IEEE standards and the National Electrical Code (NEC). These standards provide guidelines for the design, installation, and maintenance of grounding systems, ensuring that they meet safety and performance requirements.

B. Best Practices for Implementation

To ensure the effectiveness of grounding resistors, it is essential to follow best practices for implementation. This includes regular testing and maintenance of grounding systems, as well as proper installation techniques to ensure optimal performance.

VI. Challenges and Considerations

A. Environmental Factors

Environmental factors, such as soil resistivity and weather conditions, can significantly impact the performance of grounding resistors. Understanding these factors is crucial for designing effective grounding systems that can withstand various environmental conditions.

B. Technological Advancements

As technology continues to evolve, so too do the challenges and opportunities associated with grounding resistors. The integration of smart grids and the Internet of Things (IoT) presents new possibilities for enhancing grounding practices and improving electrical safety.

VII. Conclusion

In summary, grounding resistors are essential components in a wide range of industries, from power generation and telecommunications to manufacturing and renewable energy. Their ability to limit fault currents and stabilize voltage levels is critical for ensuring the safety and reliability of electrical systems. As technology advances and new challenges arise, the importance of effective grounding practices will only continue to grow. By understanding the various application scenarios and adhering to regulatory standards and best practices, industries can enhance their electrical safety and protect both personnel and equipment.

VIII. References

- Academic Journals

- Industry Reports

- Standards and Guidelines

In conclusion, grounding resistors are not just technical components; they are integral to the safety and efficiency of modern electrical systems across various industries. As we move forward, the continued focus on grounding practices will be essential in navigating the complexities of our increasingly electrified world.