The Latest Chip Adjustable Resistor Specification Sheet

I. Introduction

A. Definition of Chip Adjustable Resistors

Chip adjustable resistors, also known as variable resistors or potentiometers, are electronic components that allow for the adjustment of resistance within a circuit. Unlike fixed resistors, which have a set resistance value, adjustable resistors enable designers to fine-tune circuit performance by varying resistance levels. This flexibility is crucial in many applications, from simple consumer electronics to complex industrial systems.

B. Importance in Electronic Circuits

In electronic circuits, the ability to adjust resistance can significantly impact performance, efficiency, and functionality. Chip adjustable resistors are essential for tasks such as calibrating signal levels, controlling current flow, and setting bias points in amplifiers. Their versatility makes them invaluable in a wide range of applications.

C. Purpose of the Specification Sheet

The purpose of this specification sheet is to provide a comprehensive overview of the latest chip adjustable resistors, detailing their key specifications, performance characteristics, and selection criteria. This information is vital for engineers and designers who need to choose the right components for their projects.

II. Overview of Chip Adjustable Resistors

1. Description and Functionality

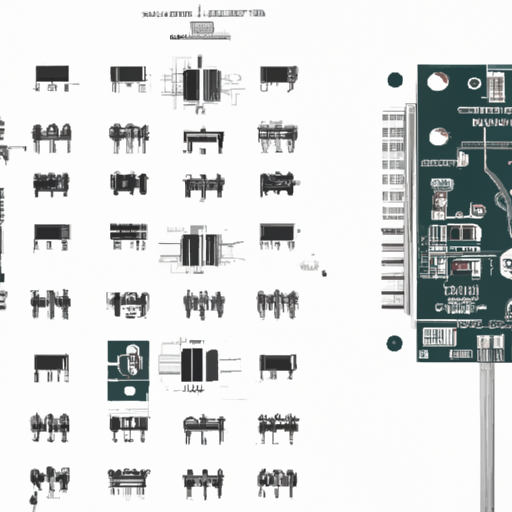

Chip adjustable resistors are compact, surface-mount devices designed to provide variable resistance in electronic circuits. They typically consist of a resistive element and a mechanism for adjusting the resistance, such as a rotary knob or a slider. The adjustment can be made manually or electronically, depending on the design.

2. Types of Adjustable Resistors

There are several types of adjustable resistors, including:

Trimmer Resistors: These are small, adjustable resistors used for fine-tuning circuits. They are often used in calibration applications.

Potentiometers: These are more versatile and can be used in various applications, including volume controls in audio equipment and as position sensors.

1. Consumer Electronics

In consumer electronics, chip adjustable resistors are commonly used in devices such as televisions, audio systems, and smartphones. They allow users to adjust settings like volume, brightness, and contrast.

2. Automotive

In the automotive industry, adjustable resistors are used in various applications, including climate control systems, seat adjustments, and electronic stability control systems.

3. Telecommunications

Telecommunications equipment relies on adjustable resistors for signal conditioning and tuning, ensuring optimal performance in communication systems.

4. Industrial Equipment

In industrial settings, adjustable resistors are used in control systems, automation equipment, and instrumentation, where precise adjustments are necessary for accurate operation.

III. Key Specifications of Chip Adjustable Resistors

1. Minimum and Maximum Resistance Values

The resistance range of adjustable resistors varies widely, with some offering a range from a few ohms to several megaohms. This range is crucial for ensuring compatibility with different circuit designs.

2. Tolerance Levels

Tolerance levels indicate how much the actual resistance can deviate from the specified value. Common tolerance levels for adjustable resistors range from ±1% to ±20%, depending on the application requirements.

1. Definition and Importance

Power rating refers to the maximum amount of power that a resistor can dissipate without overheating. It is a critical specification that ensures the resistor operates safely within its limits.

2. Typical Power Ratings for Different Applications

Power ratings for chip adjustable resistors typically range from 0.1W to 1W for general applications, while higher power ratings may be required for industrial or automotive applications.

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature. It is expressed in parts per million per degree Celsius (ppm/°C).

2. Impact on Performance

A low temperature coefficient is desirable, as it ensures stable performance across varying temperatures, which is particularly important in precision applications.

1. Common Package Types

Chip adjustable resistors are available in various package types, including surface-mount devices (SMD) and through-hole packages. SMDs are preferred for modern electronics due to their compact size and ease of integration.

2. Dimensions and Weight Considerations

The dimensions and weight of adjustable resistors can vary significantly, impacting the overall design of the circuit. Smaller components are often favored in portable devices to save space and reduce weight.

IV. Performance Characteristics

1. Definition of Linearity

Linearity refers to how consistently the resistance changes in response to adjustments. A linear response is crucial for applications requiring precise control.

2. Importance of Smooth Adjustability

Smooth adjustability ensures that users can make fine-tuned adjustments without abrupt changes in resistance, which is essential for applications like audio volume control.

1. Factors Affecting Stability

Stability can be influenced by factors such as temperature, humidity, and mechanical stress. High-quality adjustable resistors are designed to minimize these effects.

2. Testing Methods for Reliability

Manufacturers often conduct rigorous testing, including thermal cycling and humidity tests, to ensure the reliability of adjustable resistors in various environments.

1. Operating Temperature Range

The operating temperature range specifies the temperatures within which the resistor can function effectively. Most chip adjustable resistors operate within a range of -40°C to +125°C.

2. Humidity and Moisture Resistance

Moisture resistance is crucial for applications in humid environments. Many adjustable resistors are designed to withstand high humidity levels without performance degradation.

V. Comparison with Fixed Resistors

1. Flexibility in Design

Adjustable resistors offer designers the flexibility to modify circuit parameters, making them ideal for prototyping and testing.

2. Cost-Effectiveness in Prototyping

Using adjustable resistors can reduce costs during the prototyping phase, as they eliminate the need for multiple fixed resistors with different values.

1. Size Constraints

While adjustable resistors provide flexibility, they can be larger than fixed resistors, which may pose challenges in compact designs.

2. Potential for Mechanical Wear

Mechanical adjustable resistors can experience wear over time, leading to reduced performance. This is a consideration for applications requiring long-term reliability.

VI. Selection Criteria for Chip Adjustable Resistors

1. Understanding Circuit Needs

Before selecting an adjustable resistor, it is essential to understand the specific requirements of the circuit, including resistance range, power rating, and environmental conditions.

2. Matching Specifications to Application

Choosing the right specifications ensures optimal performance and reliability in the intended application.

1. Reputation and Reliability

Selecting components from reputable manufacturers can ensure quality and reliability, reducing the risk of failure in critical applications.

2. Availability of Technical Support

Access to technical support can be invaluable during the design and implementation phases, helping engineers troubleshoot issues and optimize performance.

VII. Future Trends in Chip Adjustable Resistors

1. Miniaturization and Integration

As electronic devices continue to shrink in size, the demand for smaller, more integrated adjustable resistors is increasing. This trend is driving innovation in design and manufacturing.

2. Smart Resistors and IoT Applications

The rise of the Internet of Things (IoT) is leading to the development of smart adjustable resistors that can be controlled remotely, providing enhanced functionality and convenience.

1. Growth in Demand Across Industries

The demand for adjustable resistors is expected to grow across various industries, driven by the increasing complexity of electronic systems and the need for precise control.

2. Innovations in Design and Functionality

Ongoing research and development are likely to yield new designs and functionalities, further expanding the applications of chip adjustable resistors.

VIII. Conclusion

A. Recap of Key Points

Chip adjustable resistors play a vital role in modern electronic circuits, offering flexibility and precision in resistance adjustment. Understanding their specifications, performance characteristics, and selection criteria is essential for engineers and designers.

B. Importance of Understanding Specifications

A thorough understanding of the specifications outlined in this sheet can help ensure that the right adjustable resistors are chosen for specific applications, leading to improved performance and reliability.

C. Encouragement for Further Research and Development

As technology continues to evolve, ongoing research and development in the field of adjustable resistors will be crucial. Engineers and designers are encouraged to stay informed about the latest advancements and trends to leverage the full potential of these versatile components.

IX. References

A. Suggested Reading and Resources

- "Electronic Components: A Complete Reference for Project Builders" by Delton T. Horn

- "The Art of Electronics" by Paul Horowitz and Winfield Hill

B. Manufacturer Websites and Technical Papers

- Vishay Intertechnology: [www.vishay.com](http://www.vishay.com)

- Bourns Inc.: [www.bourns.com](http://www.bourns.com)

This blog post provides a comprehensive overview of chip adjustable resistors, their specifications, applications, and future trends, serving as a valuable resource for engineers and designers in the electronics field.