What Kind of Product Are Ceramic Resistors?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors available, ceramic resistors stand out due to their unique properties and applications. This article aims to provide a comprehensive understanding of ceramic resistors, exploring their composition, characteristics, applications, and how they compare to other resistor types. By the end, readers will have a clearer picture of the significance of ceramic resistors in modern electronic circuits.

II. Understanding Resistors

A. Basic Function of Resistors in Electrical Circuits

Resistors are passive electronic components that limit the flow of electric current in a circuit. They are essential for controlling voltage levels, dividing voltages, and protecting sensitive components from excessive current. By providing resistance, they help maintain the desired performance of electronic devices.

B. Types of Resistors

Resistors can be categorized into several types based on their functionality and construction:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in various applications.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these allow users to adjust the resistance value as needed.

3. **Specialty Resistors**: This category includes precision resistors, thermistors, and photoresistors, each designed for specific applications.

C. Role of Resistors in Controlling Current and Voltage

Resistors are fundamental in controlling current and voltage levels in circuits. By adjusting the resistance, engineers can design circuits that operate efficiently and safely, ensuring that components receive the appropriate voltage and current.

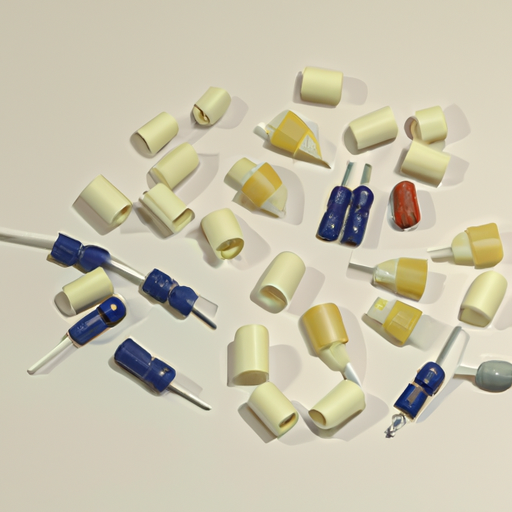

III. What Are Ceramic Resistors?

A. Composition and Materials Used

Ceramic resistors are made from a combination of ceramic substrates and resistive materials. The ceramic substrate provides mechanical strength and thermal stability, while the resistive materials determine the resistor's electrical properties.

1. **Ceramic Substrate**: Typically made from materials like alumina, the ceramic substrate is non-conductive and can withstand high temperatures.

2. **Resistive Materials**: Commonly used materials include metal oxides, carbon, and other compounds that provide the desired resistance characteristics.

B. Manufacturing Process

The manufacturing of ceramic resistors involves several steps:

1. **Preparation of Materials**: The raw materials are carefully selected and prepared.

2. **Screen Printing**: The resistive material is applied to the ceramic substrate using screen printing techniques.

3. **Sintering**: The printed substrate is heated in a furnace to bond the resistive material to the ceramic.

4. **Trimming and Testing**: The resistors are trimmed to achieve the desired resistance values and undergo rigorous quality control measures to ensure reliability.

C. Types of Ceramic Resistors

Ceramic resistors can be classified into three main types:

1. **Thick Film Resistors**: These resistors use a thick layer of resistive material and are known for their versatility and cost-effectiveness.

2. **Thin Film Resistors**: With a thinner layer of resistive material, these resistors offer higher precision and stability.

3. **Power Resistors**: Designed to handle high power levels, these resistors are used in applications where heat dissipation is critical.

IV. Characteristics of Ceramic Resistors

A. Electrical Properties

Ceramic resistors exhibit several important electrical properties:

1. **Resistance Values**: They are available in a wide range of resistance values, making them suitable for various applications.

2. **Tolerance Levels**: Ceramic resistors typically have low tolerance levels, ensuring consistent performance.

3. **Temperature Coefficient**: This property indicates how the resistance changes with temperature, which is crucial for maintaining performance in varying conditions.

B. Physical Properties

Ceramic resistors also possess distinct physical properties:

1. **Size and Shape Variations**: They come in various sizes and shapes, allowing for flexibility in design.

2. **Thermal Stability**: Ceramic materials can withstand high temperatures without degrading, making them ideal for demanding applications.

3. **Durability and Reliability**: Ceramic resistors are known for their long lifespan and resistance to environmental factors.

C. Advantages and Disadvantages

1. Benefits of Using Ceramic Resistors

High Stability: They maintain consistent performance over a wide range of temperatures and conditions.

Durability: Their robust construction ensures longevity and reliability.

Versatility: Available in various types and configurations, they can be used in numerous applications.

2. Limitations and Potential Drawbacks

Cost: Ceramic resistors can be more expensive than other types, such as carbon resistors.

Size: Some ceramic resistors may be bulkier than their counterparts, which can be a consideration in compact designs.

V. Applications of Ceramic Resistors

A. Common Uses in Electronic Devices

Ceramic resistors are widely used in various electronic devices, including:

1. **Consumer Electronics**: Found in televisions, radios, and computers, they help regulate current and voltage.

2. **Industrial Applications**: Used in machinery and control systems, they ensure reliable operation.

3. **Automotive Electronics**: Essential for managing electrical systems in vehicles, they contribute to safety and performance.

B. Specialized Applications

Ceramic resistors also find use in specialized applications:

1. **High-Power Applications**: Their ability to handle high power makes them suitable for power supplies and amplifiers.

2. **Precision Measurement Devices**: Used in instruments that require high accuracy, such as multimeters and oscilloscopes.

3. **High-Frequency Circuits**: Their stability at high frequencies makes them ideal for RF applications.

VI. Comparison with Other Types of Resistors

A. Ceramic Resistors vs. Carbon Resistors

Carbon resistors are less expensive but may not offer the same level of stability and durability as ceramic resistors. Ceramic resistors are preferred in high-temperature applications.

B. Ceramic Resistors vs. Metal Film Resistors

Metal film resistors provide higher precision than ceramic resistors but may not handle as much power. Ceramic resistors are often chosen for their robustness in demanding environments.

C. Ceramic Resistors vs. Wire-Wound Resistors

Wire-wound resistors are excellent for high-power applications but can be bulkier. Ceramic resistors offer a good balance of size, power handling, and stability.

D. Pros and Cons of Each Type

Each type of resistor has its advantages and disadvantages, making the choice dependent on the specific requirements of the application.

VII. Future Trends in Ceramic Resistor Technology

A. Innovations in Materials and Manufacturing

Advancements in materials science are leading to the development of new ceramic compositions that enhance performance and reduce costs. Innovations in manufacturing processes are also improving efficiency and consistency.

B. Impact of Technology Advancements on Performance

As electronic devices become more compact and powerful, the demand for high-performance resistors will continue to grow. Ceramic resistors are likely to evolve to meet these demands, offering improved thermal management and miniaturization.

C. Predictions for Market Growth and Demand

The market for ceramic resistors is expected to expand as industries increasingly rely on electronic components. The growth of sectors such as automotive, telecommunications, and consumer electronics will drive demand for reliable and efficient resistors.

VIII. Conclusion

Ceramic resistors are a vital component in the landscape of electronic devices, offering unique properties that make them suitable for a wide range of applications. Their stability, durability, and versatility position them as a preferred choice in many scenarios. As technology continues to advance, the role of ceramic resistors will only become more significant, underscoring the importance of understanding these essential components in modern electronics. For those interested in delving deeper into the world of electronic components, exploring ceramic resistors is a worthwhile endeavor.

IX. References

For further reading and exploration of ceramic resistors, consider the following resources:

- Books on electronic components and circuit design

- Academic papers on resistor technology and materials science

- Industry reports on trends in electronic components and market analysis

By understanding ceramic resistors and their applications, engineers and enthusiasts alike can make informed decisions in their electronic designs and projects.