What are the Product Features of Resistor 5?

I. Introduction

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling current flow. Among the various types of resistors available, Resistor 5 stands out due to its unique features and specifications. This article aims to provide an in-depth look at Resistor 5, exploring its product features, applications, and advantages over other resistors. By understanding these aspects, engineers and hobbyists alike can make informed decisions when selecting resistors for their projects.

II. Understanding Resistors

A. Basic Principles of Resistors

At the core of resistor functionality lies Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R). This relationship is expressed mathematically as:

\[ V = I \times R \]

Resistors are used in circuits to limit current, divide voltages, and protect sensitive components from excessive current.

B. Types of Resistors

Resistors come in various types, each serving different purposes:

1. **Fixed Resistors**: These resistors have a constant resistance value and are commonly used in most electronic applications.

2. **Variable Resistors**: Also known as potentiometers, these allow users to adjust the resistance value, making them ideal for applications like volume controls.

3. **Specialty Resistors**: These include thermistors, photoresistors, and others designed for specific applications, such as temperature sensing or light detection.

III. Overview of Resistor 5

A. General Specifications

Resistor 5 is characterized by several key specifications:

1. **Resistance Value**: Resistor 5 typically offers a range of resistance values, allowing it to be used in various applications.

2. **Tolerance Levels**: The tolerance of Resistor 5 indicates how much the actual resistance can vary from its stated value, usually expressed as a percentage.

3. **Power Rating**: This specification indicates the maximum power the resistor can dissipate without being damaged, usually measured in watts.

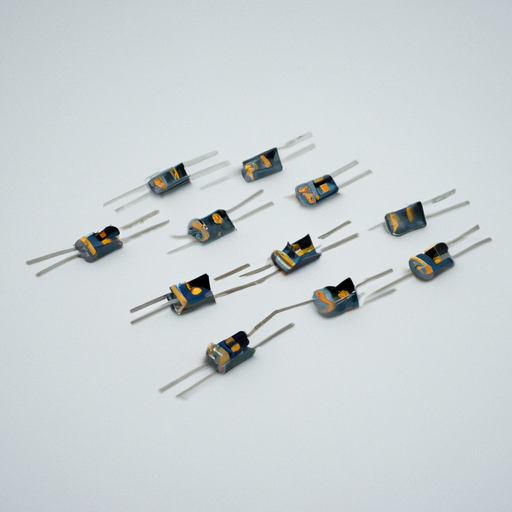

B. Physical Characteristics

The physical attributes of Resistor 5 contribute to its performance:

1. **Size and Form Factor**: Resistor 5 is available in various sizes, making it suitable for both compact and larger circuit designs.

2. **Material Composition**: Typically made from carbon film, metal film, or wire-wound materials, the composition affects the resistor's performance and durability.

3. **Color Coding and Marking**: Resistor 5 features standardized color codes that indicate its resistance value and tolerance, facilitating easy identification.

IV. Key Features of Resistor 5

A. High Precision and Accuracy

One of the standout features of Resistor 5 is its high precision and accuracy:

1. **Tolerance Specifications**: With low tolerance levels, Resistor 5 ensures that the resistance value remains consistent, which is critical in precision applications.

2. **Temperature Coefficient**: This feature indicates how much the resistance changes with temperature, allowing for reliable performance in varying environmental conditions.

B. Stability and Reliability

Resistor 5 is designed for long-term stability and reliability:

1. **Long-term Performance**: It maintains its specifications over time, reducing the need for frequent replacements.

2. **Environmental Resistance**: Resistor 5 is often built to withstand harsh conditions, including humidity, temperature fluctuations, and mechanical stress.

C. Versatility in Applications

Resistor 5's versatility makes it suitable for a wide range of applications:

1. **Use in Various Electronic Devices**: From consumer electronics to industrial machinery, Resistor 5 can be found in numerous devices.

2. **Compatibility with Different Circuit Designs**: Its specifications allow it to be integrated into both simple and complex circuit designs.

V. Performance Metrics

A. Electrical Performance

The electrical performance of Resistor 5 is critical for its functionality:

1. **Voltage Rating**: Resistor 5 is designed to handle specific voltage levels, ensuring safe operation within its limits.

2. **Current Handling Capacity**: This metric indicates the maximum current the resistor can handle without overheating or failing.

B. Thermal Performance

Thermal performance is another essential aspect:

1. **Heat Dissipation Characteristics**: Resistor 5 is engineered to dissipate heat effectively, preventing damage during operation.

2. **Operating Temperature Range**: It can function within a specified temperature range, ensuring reliability in various environments.

VI. Applications of Resistor 5

Resistor 5 finds applications across multiple sectors:

A. Consumer Electronics

In consumer electronics, Resistor 5 is used in devices such as televisions, smartphones, and audio equipment, where precise control of current is essential.

B. Industrial Applications

In industrial settings, Resistor 5 is employed in machinery and control systems, ensuring stable operation and protection against electrical surges.

C. Automotive Electronics

Resistor 5 plays a vital role in automotive electronics, including engine control units and safety systems, where reliability and precision are paramount.

D. Telecommunications

In telecommunications, Resistor 5 is used in signal processing and transmission systems, helping to maintain signal integrity and reduce noise.

VII. Comparison with Other Resistors

A. Resistor 5 vs. Standard Resistors

Compared to standard resistors, Resistor 5 offers enhanced precision and stability, making it a preferred choice for critical applications.

B. Resistor 5 vs. Specialty Resistors

While specialty resistors may excel in specific applications, Resistor 5 provides a balanced performance across various uses, making it more versatile.

C. Cost-effectiveness and Value Proposition

Despite its advanced features, Resistor 5 remains cost-effective, providing excellent value for both hobbyists and professionals.

VIII. Installation and Usage Guidelines

A. Best Practices for Installation

To ensure optimal performance, follow these best practices during installation:

1. **Proper Orientation**: Ensure the resistor is installed in the correct orientation, especially in polarized circuits.

2. **Adequate Spacing**: Allow for sufficient spacing between resistors to prevent overheating.

B. Common Mistakes to Avoid

Avoid these common mistakes:

1. **Overloading**: Do not exceed the power rating of Resistor 5, as this can lead to failure.

2. **Incorrect Value Selection**: Always double-check the resistance value to ensure it meets the circuit requirements.

C. Maintenance and Troubleshooting Tips

Regular maintenance can prolong the life of Resistor 5:

1. **Visual Inspections**: Periodically check for signs of damage or wear.

2. **Testing**: Use a multimeter to test the resistance value and ensure it remains within specifications.

IX. Conclusion

In summary, Resistor 5 is a versatile and reliable component that offers high precision, stability, and a wide range of applications. Understanding its features and specifications is crucial for selecting the right resistor for specific projects. As technology continues to evolve, the demand for advanced resistors like Resistor 5 will likely increase, paving the way for innovations in electronic design and functionality.

X. References

1. Academic papers and articles on resistor technology.

2. Manufacturer specifications for Resistor 5.

3. Industry standards and guidelines for electronic components.

By understanding the product features of Resistor 5, engineers and hobbyists can make informed decisions that enhance the performance and reliability of their electronic projects.