What are the Purchasing Models of the Latest Supercapacitor Equipment Components?

I. Introduction

Supercapacitors, also known as ultracapacitors, are energy storage devices that bridge the gap between traditional capacitors and batteries. They are characterized by their ability to store and release energy quickly, making them essential in applications requiring rapid charge and discharge cycles. As technology advances, the demand for supercapacitor equipment components has surged, leading to the development of various purchasing models tailored to meet the needs of manufacturers and suppliers. This blog post will explore the different purchasing models for supercapacitor components, their advantages and disadvantages, and the factors influencing the choice of these models.

II. Understanding Supercapacitor Technology

A. Brief History and Evolution of Supercapacitors

The concept of supercapacitors dates back to the 1950s, but it wasn't until the 1990s that they gained significant traction in the market. Initially used in niche applications, advancements in materials science and manufacturing processes have expanded their use across various industries, including automotive, renewable energy, and consumer electronics.

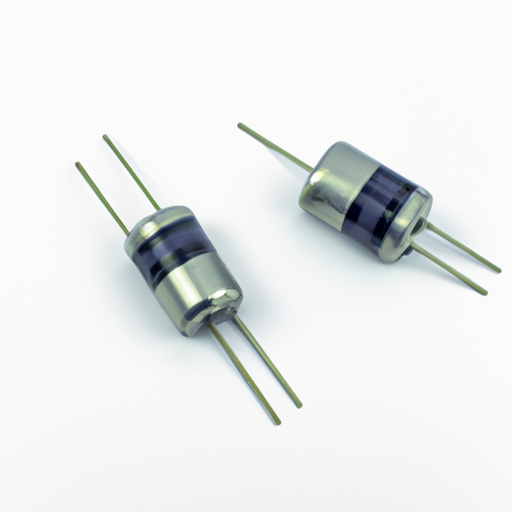

B. Key Components of Supercapacitors

Supercapacitors consist of three primary components:

1. **Electrodes**: Typically made from carbon-based materials, electrodes are crucial for energy storage. Their surface area and conductivity directly impact the performance of the supercapacitor.

2. **Electrolytes**: The electrolyte facilitates ion movement between the electrodes. It can be aqueous or organic, with each type offering different performance characteristics.

3. **Separators**: These materials prevent short circuits between the electrodes while allowing ionic movement. The choice of separator material can influence the supercapacitor's efficiency and lifespan.

C. Applications of Supercapacitors in Various Industries

Supercapacitors are used in a wide range of applications, including:

Electric vehicles: For regenerative braking and energy storage.

Renewable energy systems: To store energy from solar and wind sources.

Consumer electronics: In devices requiring quick bursts of energy, such as cameras and smartphones.

III. Purchasing Models Overview

A. Definition of Purchasing Models

Purchasing models refer to the strategies and frameworks that organizations use to acquire goods and services. In the context of supercapacitor components, these models dictate how companies source their materials, manage supplier relationships, and control costs.

B. Importance of Selecting the Right Purchasing Model

Choosing the appropriate purchasing model is critical for optimizing supply chain efficiency, managing costs, and ensuring the timely availability of components. The right model can enhance a company's competitive edge in the rapidly evolving supercapacitor market.

IV. Common Purchasing Models for Supercapacitor Components

A. Direct Purchase

1. Description and Process

Direct purchasing involves acquiring components directly from manufacturers or suppliers without intermediaries. This model is straightforward and often used for standard components.

2. Advantages and Disadvantages

**Advantages**:

- Lower costs due to the absence of middlemen.

- Direct communication with suppliers, leading to better negotiation opportunities.

**Disadvantages**:

- Limited flexibility in terms of order quantities.

- Potentially longer lead times if suppliers are located far away.

B. Bulk Purchasing

1. Description and Process

Bulk purchasing entails buying large quantities of components at once, often at discounted rates. This model is suitable for companies with predictable demand.

2. Advantages and Disadvantages

**Advantages**:

- Cost savings through volume discounts.

- Reduced frequency of orders, leading to lower administrative costs.

**Disadvantages**:

- Risk of overstocking if demand fluctuates.

- Storage costs for large inventories.

C. Just-in-Time (JIT) Purchasing

1. Description and Process

JIT purchasing focuses on acquiring components only as they are needed in the production process. This model minimizes inventory costs and reduces waste.

2. Advantages and Disadvantages

**Advantages**:

- Lower inventory holding costs.

- Increased efficiency in production processes.

**Disadvantages**:

- Vulnerability to supply chain disruptions.

- Requires strong relationships with reliable suppliers.

D. Long-term Contracts

1. Description and Process

Long-term contracts involve agreements with suppliers to provide components over an extended period, often at predetermined prices. This model is beneficial for companies with stable demand.

2. Advantages and Disadvantages

**Advantages**:

- Price stability and predictability.

- Stronger supplier relationships.

**Disadvantages**:

- Reduced flexibility to switch suppliers or adjust orders.

- Potential for overcommitment if demand decreases.

E. Consortium Purchasing

1. Description and Process

Consortium purchasing involves multiple companies collaborating to purchase components collectively. This model leverages the combined purchasing power of the group.

2. Advantages and Disadvantages

**Advantages**:

- Enhanced bargaining power leading to better pricing.

- Shared risks and costs among consortium members.

**Disadvantages**:

- Complexity in decision-making and coordination.

- Potential conflicts of interest among members.

V. Factors Influencing the Choice of Purchasing Model

A. Cost Considerations

Cost is a primary factor influencing purchasing decisions. Companies must evaluate the total cost of ownership, including purchase price, storage, and logistics.

B. Supply Chain Dynamics

The stability and reliability of the supply chain can dictate the choice of purchasing model. Companies in volatile markets may prefer JIT or long-term contracts to mitigate risks.

C. Demand Variability

Fluctuations in demand can impact purchasing strategies. Companies with unpredictable demand may lean towards direct or JIT purchasing to maintain flexibility.

D. Supplier Relationships

Strong relationships with suppliers can facilitate better terms and conditions, influencing the choice of purchasing model. Companies with established partnerships may benefit from long-term contracts.

E. Technological Advancements

Emerging technologies, such as AI and data analytics, can enhance purchasing decisions by providing insights into market trends and supplier performance.

VI. Case Studies

A. Example of a Company Using Direct Purchase Model

A small electronics manufacturer opted for direct purchasing to source supercapacitor components. By eliminating intermediaries, they reduced costs and established direct communication with suppliers, leading to improved product quality.

B. Example of a Company Utilizing Bulk Purchasing

A large automotive company implemented bulk purchasing for supercapacitor components to support its electric vehicle production. This strategy allowed them to negotiate favorable pricing and streamline their supply chain.

C. Example of a Company Implementing JIT Purchasing

A renewable energy firm adopted a JIT purchasing model to align component acquisition with project timelines. This approach minimized inventory costs and improved cash flow management.

D. Example of a Company Engaged in Long-term Contracts

A consumer electronics company entered into long-term contracts with suppliers for supercapacitor components, ensuring price stability and reliable supply for their production needs.

VII. Future Trends in Purchasing Models for Supercapacitor Components

A. Impact of Digital Transformation on Purchasing Models

Digital transformation is reshaping purchasing models, enabling companies to leverage e-commerce platforms and digital supply chain management tools for more efficient procurement processes.

B. Sustainability Considerations in Purchasing Decisions

As sustainability becomes a priority, companies are increasingly considering the environmental impact of their purchasing decisions, leading to a rise in eco-friendly sourcing practices.

C. The Role of Artificial Intelligence and Data Analytics

AI and data analytics are revolutionizing purchasing strategies by providing insights into market trends, supplier performance, and demand forecasting, allowing companies to make informed decisions.

VIII. Conclusion

Selecting the right purchasing model for supercapacitor equipment components is crucial for optimizing supply chain efficiency and managing costs. As technology continues to evolve, companies must remain adaptable and consider various factors influencing their purchasing decisions. By understanding the different purchasing models and their implications, organizations can position themselves for success in the competitive landscape of supercapacitor technology.

IX. References

A comprehensive list of academic papers, industry reports, and other resources used in the research will be provided to support the information presented in this blog post.

---

This blog post provides a detailed exploration of the purchasing models for supercapacitor equipment components, offering insights into their advantages, disadvantages, and the factors influencing their selection. By understanding these models, companies can make informed decisions that enhance their operational efficiency and competitiveness in the market.